What are the main pieces of equipment in a large-scale edible oil processing plant?

Edible oil is an indispensable food in daily life, and a large-scale edible oil processing plant require a series of specialized equipment to ensure production efficiency and product quality. The following are some of the main pieces of equipment typically included in a large-scale edible oil processing plant:

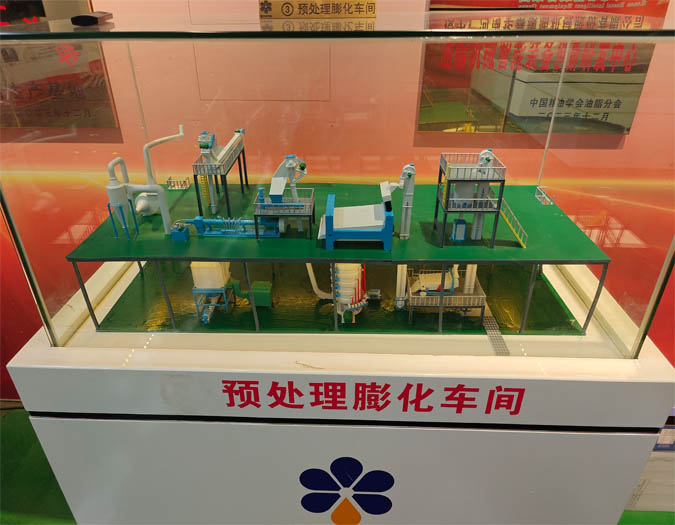

Raw Material Pre-processing Equipment:

Raw material pre-processing is the first step in edible oil processing, mainly involving cleaning, shelling, crushing and softening, puffing, flaking, and steaming/roasting. This primarily includes cleaning equipment (magnetic separator, vibrating cleaning screen, destoner), shelling machine, crusher, softening pot, puffing machine, flaking machine, and steaming/roasting pot.

Oil Extraction Equipment

The pressing equipment is one of the core pieces of equipment in the pressing method of oil extraction. Common pressing equipment includes screw oil press and hydraulic oil press. Screw oil press is suitable for large-scale continuous production, while hydraulic oil press is suitable for processing some special oilseeds. As a key piece of equipment in the pressing method, some oilseeds that require pre-pressing are also pressed first using pressing equipment before being fed into the solvent extraction workshop for solvent extraction.

2. Solvent Extraction Equipment

Solvent extraction is a common method in large-scale edible oil processing plant. Solvent extraction equipment includes solvent extractors, desolventizer toaster, and solvent recovery unit, which further separate the oil through solvent extraction.

For oilseeds with low oil content, such as soybeans and rice bran, they are usually pre-treated before entering the solvent extraction workshop. However, for oilseeds with high oil content, such as peanuts and sunflower seeds, pre-treatment and pre-pressing are required before entering the solvent extraction workshop to obtain more oil.

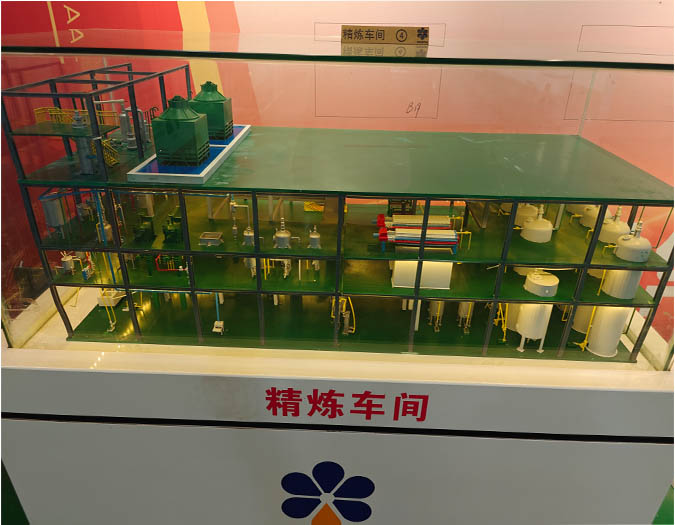

To remove impurities from crude oil and improve the quality of edible oil, refining is necessary. Refining equipment typically includes degumming pan, deacidification tower, decolorization towes, and deodorization unit, used to remove phospholipids, free fatty acids, pigments, and odors.

In addition, the edible oil processing plant also needs some auxiliary equipment, such as steam boiler, cooling tower, conveyor belt and electrical control systems. These equipments play a supporting and guaranteeing role in the whole production process, ensuring the efficient and safe operation of the factory.

In summary, the equipment in a large-scale edible oil processing plant includes pretreatment equipment, oil extraction equipment, refining equipment, and other auxiliary equipment. These various types of equipment work together to complete the transformation process from raw materials to finished products, providing consumers with high-quality edible oil products.